Instaclave Aerospace ™

Current Projects:

Instaclave Technologies has developed a new fabrication process for Aerospace Grade carbon fiber. Using the existing carbon fiber material and companion resins of your traditional process, our new, innovative process makes a stronger part.

By modifying the carbon fiber materials geometry and implementing our DPART process, we have increased the strength of the finished part by 30%

- 30% stronger means we can use less material for the same strength and load. Less material means a less expensive part.

- 30% less material means a lighter part. In the UAV world, drones and electric flying taxis, it means greater range.

Completing Beta Development:

We have cracked the code to create reliable Inflatable Carbon Fiber. This technology will change manufacturing in a variety of markets.

No Molds, no Autoclaves, minimal Energy, no waiting. Inflates and hardens in milliseconds, both in Earth Atmosphere and in Space.

Mars Antenna Array Project:

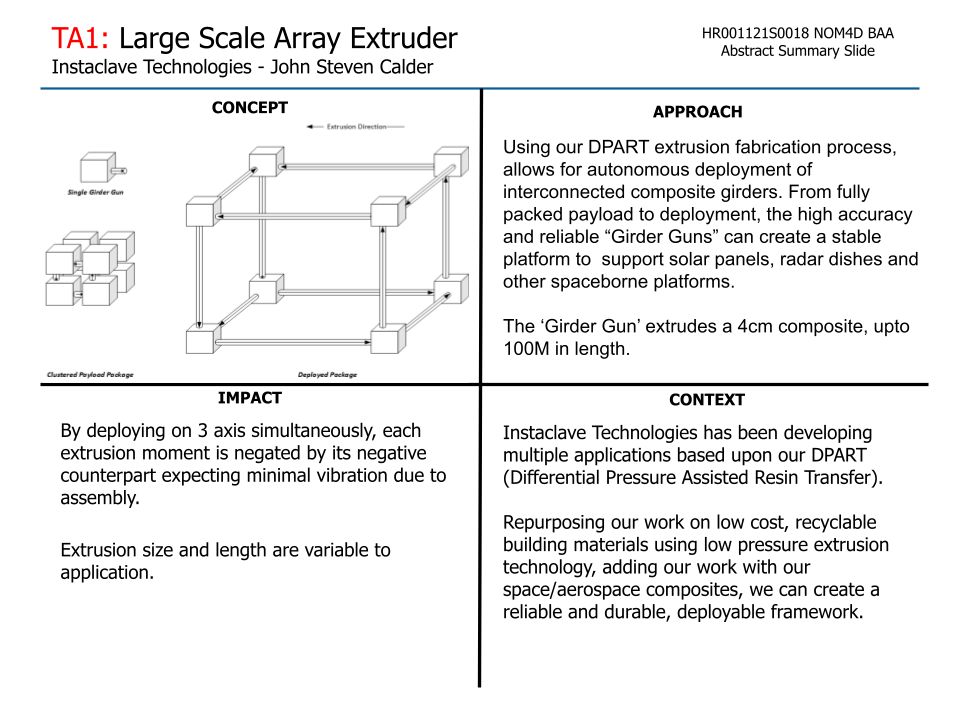

Under a proposal for DARPA, we created a system to deploy massive arrays in Space.

Named the Large Scale Array Extruder. Key to this development is what we call the Girder Gun. Each gun is the size of a lunchbox, that can deploy a 6cm Carbon Fiber tube, at 1/2 meter per second, up to 150 meters in length.

Using our internally developed fail safe bonding system and Floating Mandrel System, the fabrication methodology can create complex shapes by connecting multiple guns in 3 axis.

Stay tuned to this space as lots more to come!