About Us

We are a Research & Development company specializing in material sciences applying our Differential Pressure Assisted Resin Transfer (DPART) fabrication process.

Our DPART process is making compatible aerospace parts, using the same materials and resins that are 30% stronger than standard VARTM produced parts. Strong means lighter, as we require less material. Less material means cheaper. Lighter means extended ranges to UAV & Drone markets.

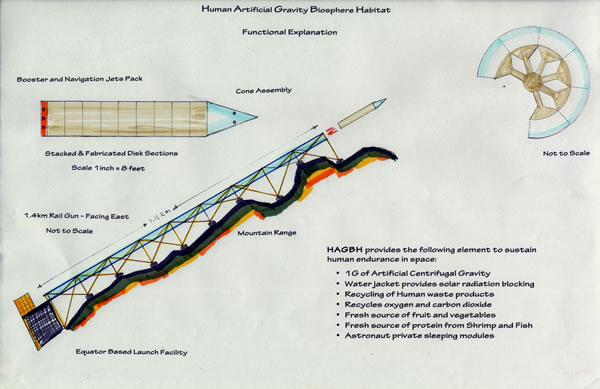

Founded by John Steven Calder, Instaclave Technologies is currently under intensive product and business development. The design and creation of the DPART derived from the desire to fabricate extremely large structures in space. The goal is to create structures so large and reliable they can contain atmospheres, provide centrifugal gravity via rotation of the structure and insulate human beings from the negative effects of extended living in space.

After reviewing material that would be compatible with such systems, it became clear that the only modern material capable of operating in the harsh environment of space is a carbon fiber class (or a variant).

However current applications of carbon fiber components require the part to be formed in a mold, under intense vacuum, to remove oxygen from the interior layers. The part must also be cooked in an autoclave oven for an extended period of time.

Since there is no access to molds or autoclave ovens in space, an alternative solution is required.

Solving these problems lies the seeds of the DPART Process